Mating functional gears to circular gears

-

Edward French

- Old Timer

- Posts: 15

- Joined: Wed Jan 01, 2014 4:37 am

Mating functional gears to circular gears

Are there any guidelines for creating functional or non-circular gears and having them mate with circular gears?

Re: Mating functional gears to circular gears

Hi:

I'm unaware of any published guidelines. This likely due to the unlimited

number of possible combinations.

My thoughts are:

In general, the maximum radius of concavity

of the functional gear must not be less than the outside radius of any mating

circular gear and the shaft must allow motion equal to the maximum convexity

and maximum concavity as a range.

Other than that your usually good to go ,BUT, functional gears vary their

pressure angle on every tooth, so as you distort more from circular, you do

get increased wear I think..like everything else, moderation is probably advisable.

If you do make such a set, do me a favor and post a picture.. Id love to see such

a thing run..

Art

I'm unaware of any published guidelines. This likely due to the unlimited

number of possible combinations.

My thoughts are:

In general, the maximum radius of concavity

of the functional gear must not be less than the outside radius of any mating

circular gear and the shaft must allow motion equal to the maximum convexity

and maximum concavity as a range.

Other than that your usually good to go ,BUT, functional gears vary their

pressure angle on every tooth, so as you distort more from circular, you do

get increased wear I think..like everything else, moderation is probably advisable.

If you do make such a set, do me a favor and post a picture.. Id love to see such

a thing run..

Art

Re: Mating functional gears to circular gears

In order to mesh non-circular gears with circular gears, the distance between the instantaneous axis of rotation has to change over time. Depending on the application, that degree of freedom may allow for constant pressure angle non-circular gears.ArtF wrote: ...

Other than that your usually good to go ,BUT, functional gears vary their

pressure angle on every tooth, so as you distort more from circular, you do

get increased wear I think..like everything else, moderation is probably advisable.

...

-

Edward French

- Old Timer

- Posts: 15

- Joined: Wed Jan 01, 2014 4:37 am

Re: Mating functional gears to circular gears

Here's a video of a triangular gear running: http://smg.photobucket.com/user/etfrenc ... 1.mp4.html

Photobucket still seems to be down for me , but you may be able to get on. If not I can send the video.

Is there a way to calculate the pressure angle between circular and non-circular gears?

Photobucket still seems to be down for me , but you may be able to get on. If not I can send the video.

Is there a way to calculate the pressure angle between circular and non-circular gears?

Re: Mating functional gears to circular gears

The video didn't work for me, but based on 'rose engine' it seems like you're looking for some kind of 'spirograph lathe' thing. Maybe something like the one at the start of this video:Edward French wrote: Here's a video of a triangular gear running: http://smg.photobucket.com/user/etfrenc ... 1.mp4.html

...

Is there a way to calculate the pressure angle between circular and non-circular gears?

https://www.youtube.com/watch?v=4XDIonkwTRo&t=30s

...

It seems like you're not that familiar with gear terminology or theory. The pressure angle is something that has to do with the shape and meshing properties of individual teeth, and is not necessarily determined by the shape of the gear. It can be a little tricky to measure. Depending on your situation and application it may be easier to make a complete set of gears than to measure the pressure angle of one. Alternatively, might also get satisfactory results simply by getting close.

-

Edward French

- Old Timer

- Posts: 15

- Joined: Wed Jan 01, 2014 4:37 am

Re: Mating functional gears to circular gears

I've tried multiple times to attach the video as a txt file, but it's failing to post.

Another way to ask about the pressure angle is how do I ensure the pressure angle will be less than 50 when mating circular and non-circular gears?

Another way to ask about the pressure angle is how do I ensure the pressure angle will be less than 50 when mating circular and non-circular gears?

Re: Mating functional gears to circular gears

Can you make a drawing of what you mean by pressure angle? The notion is a little ambiguous when dealing with non-circular gears.Edward French wrote: ...

Another way to ask about the pressure angle is how do I ensure the pressure angle will be less than 50 when mating circular and non-circular gears?

As far as I'm concerned, all the `rolling gears` in the attached pdf have the same pressure angle.

- Attachments

-

[The extension pdf has been deactivated and can no longer be displayed.]

Re: Mating functional gears to circular gears

>>In order to mesh non-circular gears with circular gears, the distance between the instantaneous axis of rotation has to change over time. Depending on the application, that degree of freedom may allow for constant pressure angle non-circular gears.

This sounds correct. Since the functionals are created with a 20 degree hob, there is no pressure angle variation when considered from the point of view of the hob, so there shouldn't be from the point of view

of the circular gear on that functional. Sorry if I misled, but considering the hob, I cant see where the

pressure angle would be an issue.. It IS an issue as to the circular gear being able to fit within the concavities

of the functional of course, but other than that your likely fine..

Art

This sounds correct. Since the functionals are created with a 20 degree hob, there is no pressure angle variation when considered from the point of view of the hob, so there shouldn't be from the point of view

of the circular gear on that functional. Sorry if I misled, but considering the hob, I cant see where the

pressure angle would be an issue.. It IS an issue as to the circular gear being able to fit within the concavities

of the functional of course, but other than that your likely fine..

Art

-

Edward French

- Old Timer

- Posts: 15

- Joined: Wed Jan 01, 2014 4:37 am

Re: Mating functional gears to circular gears

Thanks for the reassurance. It looks like photobucket is back online, so the video should be viewable.

Re: Mating functional gears to circular gears

cool machine...

Art

Art

Re: Mating functional gears to circular gears

Let's assume that the teeth are very small, so that we can ignore the effect of the path of contact.Edward French wrote:...

Is there a way to calculate the pressure angle between circular and non-circular gears?

Let's also assume that the tooth meshing is as with involute gears with pressure angle phi.

Let r(theta) be a polar formula for the non-circular gear's pitch profile, centred on the axle for that gear.

Then the pressure angle (as Art would think of it) is going to be equal to:

arctan( dr/dtheta / r ) +/- phi

Where dr/dtheta is the derivative with respect to angle.

Re: Mating functional gears to circular gears

So long as your using the functional gears and your circular gear is small enough to stay tangent to the

drivers curve.. then the pressure angle will be equal to the hob's, 20 degrees. And Id think youll always

want to maintain tangency when using a circular on a functional gear.

Art

-

Edward French

- Old Timer

- Posts: 15

- Joined: Wed Jan 01, 2014 4:37 am

Re: Mating functional gears to circular gears

I think all of the gears that will work on a Rose Engine would need to stay tangent. I've just started modeling functional gears. It will be interesting to see what kind of patterns will be generated.

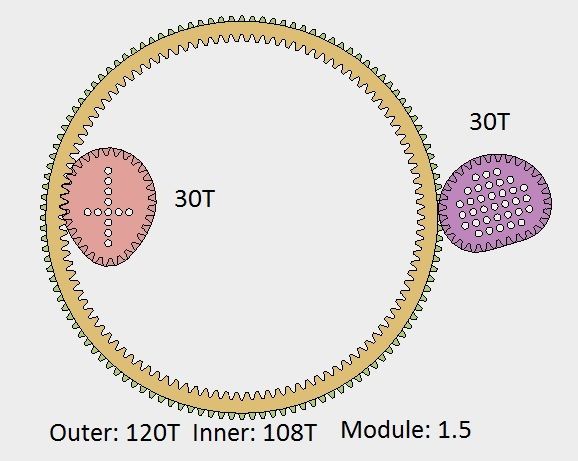

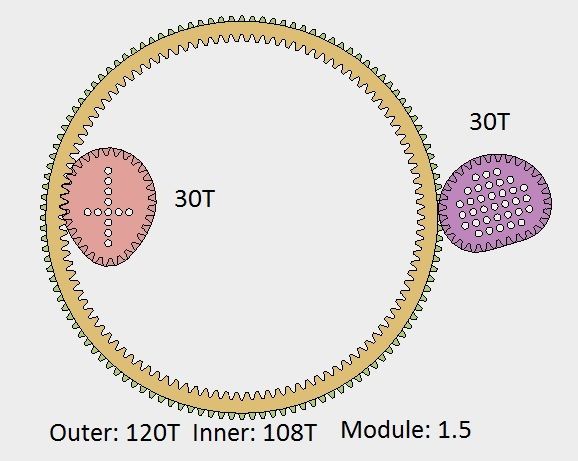

Here's a sample (We've already tried the 120T and 108T circular gears with elliptical and triangular gears).

Thanks for all of your help.

Here's a sample (We've already tried the 120T and 108T circular gears with elliptical and triangular gears).

Thanks for all of your help.

Re: Mating functional gears to circular gears

Excellent work..

Yes, I think youll be fine, in your type of operation the round gear shoudl always be in tangency so I think your fine..

Art

Yes, I think youll be fine, in your type of operation the round gear shoudl always be in tangency so I think your fine..

Art

Who is online

Users browsing this forum: No registered users and 35 guests