Worm gears

Re: Worm gears

brilliant..

Re: Worm gears

Only problem with this method is, as the tap starts it's running on the OD and it will generate OD*Pi / pitch of tap which will be totally different from the Pitch circle * Pi / pitch of tap.

Many people using this method say it's a toss up on how many teeth you finish up with. Many pre gash the number of teeth they want with a slitting saw to ensure they get the correct number they need.

I used to hob worm wheels on a hobbing machine, full enveloping wheels, 40 T or 60 T and the odd time I forgot to fully tighten the blank it finished up being driven by the hob and not the machines with 42 or 43 teeth of incorrect form being cut. Wasn't bad on a 60T wheel as it could be saved and made into a 40T but a I really wanted a market for 30T wheels to use up the scrap 40's :-)

Many people using this method say it's a toss up on how many teeth you finish up with. Many pre gash the number of teeth they want with a slitting saw to ensure they get the correct number they need.

I used to hob worm wheels on a hobbing machine, full enveloping wheels, 40 T or 60 T and the odd time I forgot to fully tighten the blank it finished up being driven by the hob and not the machines with 42 or 43 teeth of incorrect form being cut. Wasn't bad on a 60T wheel as it could be saved and made into a 40T but a I really wanted a market for 30T wheels to use up the scrap 40's :-)

John S.

Nottingham, England

Nottingham, England

Re: Worm gears

John:

Interesting.. So really to do the pinion would only require the current tangential code for a normal spur, with an added radius of the arc of the envelopment of the worm itself put into the Z, so the arc bottom is center of the spur.. ?

That at least sounds do-able, but the worm itself, short of a shaped tool I don't think is possible.. Am I wrong in that thought?

(Yours being the opinion on such things I would at all times take to the bank...) :-)

Art

Interesting.. So really to do the pinion would only require the current tangential code for a normal spur, with an added radius of the arc of the envelopment of the worm itself put into the Z, so the arc bottom is center of the spur.. ?

That at least sounds do-able, but the worm itself, short of a shaped tool I don't think is possible.. Am I wrong in that thought?

(Yours being the opinion on such things I would at all times take to the bank...) :-)

Art

Re: Worm gears

Art

Pinion I feel would be easy, it's a low helix gear with an additional z axis move in the centre.

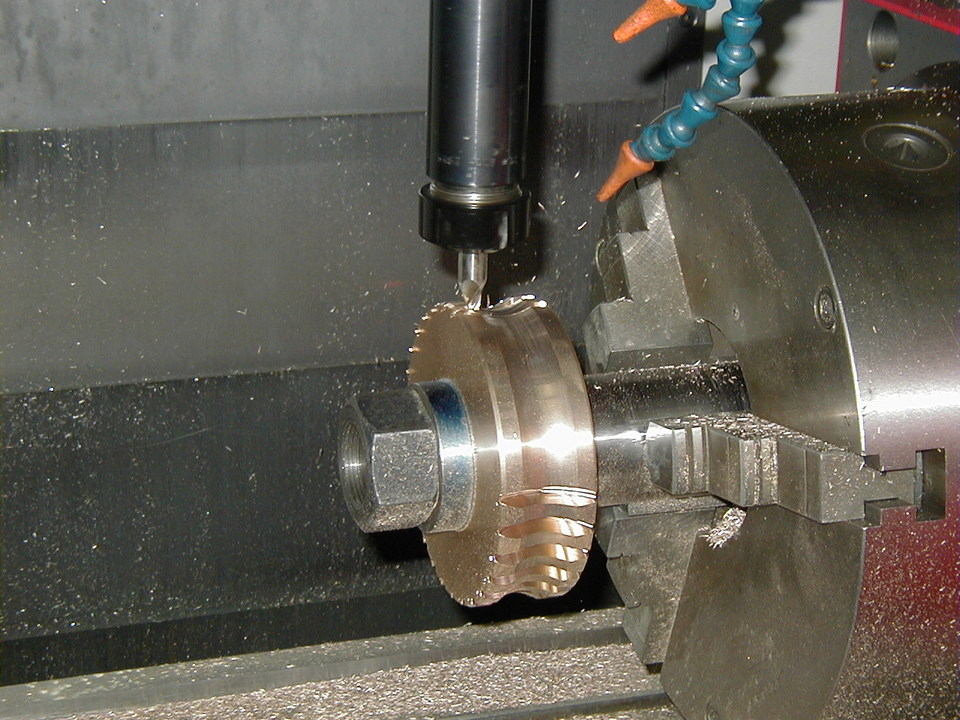

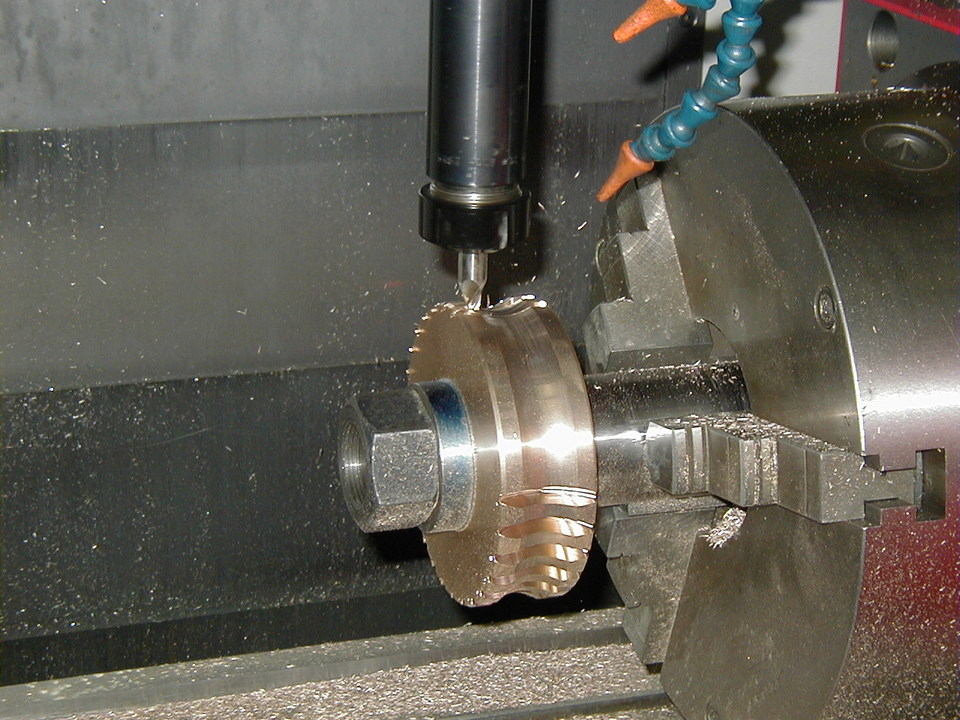

I'll include this picture stolen without credits from Bob Whorefields site as he steals everything and credits no one ;D

It would be easier using a vee cutter and as most pinions / wheels are done in a soft material i single flute cutter similar to an engraving cutter could be used. After all the most common angles would be 20 and 29 degrees or 30 for the trapezoidal guys in EU land.

Worms them selves are just screws so using anything other than a lathe is just an exercise in getting a good spanking [ mind you that's not bad at the right hands :o ]

If you were serious though it's simple job to hand write a code and mill one with the exact same cutter, or Gearotic could even spit the code out given you fill a few boxes in.

This was just a test once to see how easy iy would be to do a square thread.

Pinion I feel would be easy, it's a low helix gear with an additional z axis move in the centre.

I'll include this picture stolen without credits from Bob Whorefields site as he steals everything and credits no one ;D

It would be easier using a vee cutter and as most pinions / wheels are done in a soft material i single flute cutter similar to an engraving cutter could be used. After all the most common angles would be 20 and 29 degrees or 30 for the trapezoidal guys in EU land.

Worms them selves are just screws so using anything other than a lathe is just an exercise in getting a good spanking [ mind you that's not bad at the right hands :o ]

If you were serious though it's simple job to hand write a code and mill one with the exact same cutter, or Gearotic could even spit the code out given you fill a few boxes in.

This was just a test once to see how easy iy would be to do a square thread.

John S.

Nottingham, England

Nottingham, England

Re: Worm gears

John:

I never knew there was any helix to the pinion, it is a function of the cross angle one wants? Like 90 degree would be standard, no helix?

Art

I never knew there was any helix to the pinion, it is a function of the cross angle one wants? Like 90 degree would be standard, no helix?

Art

Re: Worm gears

Yes the helix angle of the pinion, lets just call it a wheel, is equal to the helix angle of the worm.

If you get a worm, or piece of all thread and offer it up to a spur gear it will sit canted to one side because of the helix angle.

To sit at 90 degrees [ normal setup for worm and wheel l the wheel will have to carry the same angle.

I think this picture off Google images shows it well.

If you get a worm, or piece of all thread and offer it up to a spur gear it will sit canted to one side because of the helix angle.

To sit at 90 degrees [ normal setup for worm and wheel l the wheel will have to carry the same angle.

I think this picture off Google images shows it well.

John S.

Nottingham, England

Nottingham, England

Re: Worm gears

John:

Thank you, I handn't looked into them deep enough to realize all that,

the helix is obvious once you consider it , I guess I hadnt till now. :)

Art

Thank you, I handn't looked into them deep enough to realize all that,

the helix is obvious once you consider it , I guess I hadnt till now. :)

Art

Re: Worm gears

When I tried to generate worm gears for 3D printing, I found that the tooth form changed from the top to the bottom of the gear, though probably not enough to matter much with real world gears.

http://www.thingiverse.com/thing:270309/

I imagine nobody is silly enough to try to produce the pointy bits at the top and bottom on a working part.

http://www.thingiverse.com/thing:270309/

I imagine nobody is silly enough to try to produce the pointy bits at the top and bottom on a working part.

Re: Worm gears

Hi Nate:

Those look like the pressure angle is way too high, .. or is that on purpose I wonder?

Art

Those look like the pressure angle is way too high, .. or is that on purpose I wonder?

Art

Re: Worm gears

They're designed to mesh with acme screws, so the pressure angle is - nominally - 14.5 degrees. The thing is that the screw is really only a trapezoidal rack on the plane that contains its axis, and does more interesting things as you move away from that plane. I think I also profile shifted aggressively so that the gear could 'grab' more of the screw thread.ArtF wrote: Hi Nate:

Those look like the pressure angle is way too high, .. or is that on purpose I wonder?

Re: Worm gears

>>profile shifted aggressiv ely so that t

Ahh, that would explain it.. :)

Art

Ahh, that would explain it.. :)

Art

-

Barbudania

- Old Timer

- Posts: 6

- Joined: Wed Jan 10, 2018 4:51 am

Re: Worm gears

Oh well, accept my vote for worms also

Who is online

Users browsing this forum: No registered users and 1 guest